Engineering North

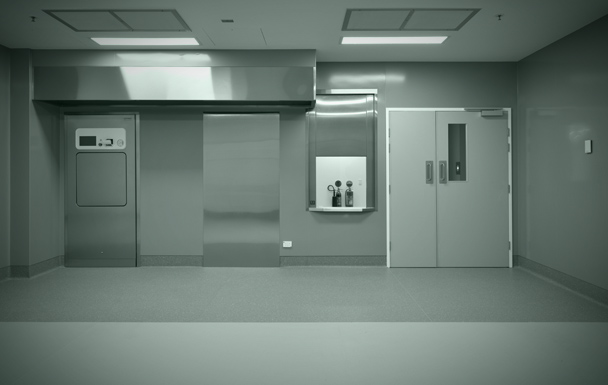

System Solutions Engineering has completed construction of a new shared laboratory facility at the University of Adelaide, co-locating multiple professors within the same operational area, to provide shared resources and equipment, minimisation of equipment duplication, improved collaboration between research and teaching groups and provision of high-grade consumables for experiments.

The new shared laboratory has been created for the faculty of Engineering, Computer and Mathematical Sciences (ECMS) and the school of Chemical Engineering and Advanced Materials and provides a high-end functional space to allow the professors, masters and PHD students to complete leading-edge research.

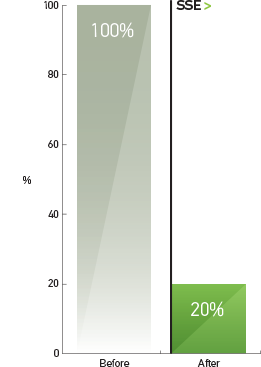

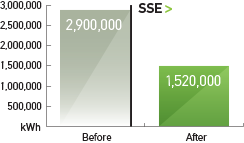

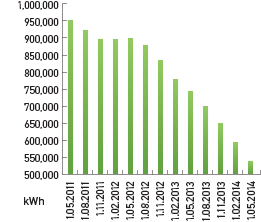

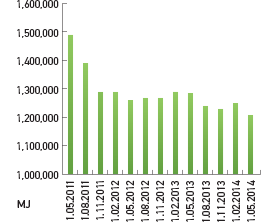

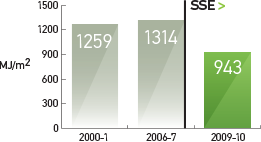

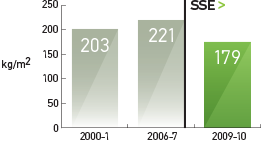

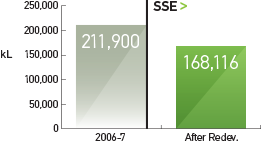

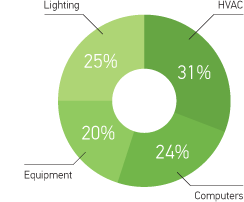

ESD/initiatives

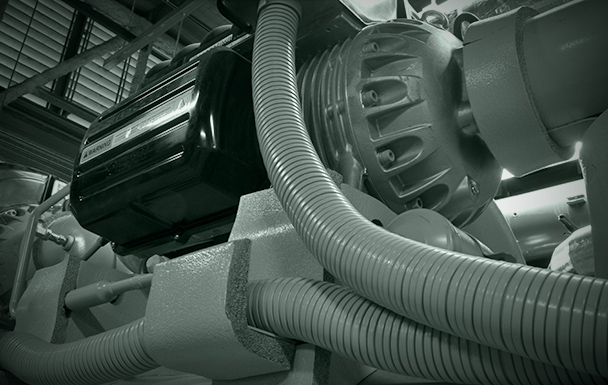

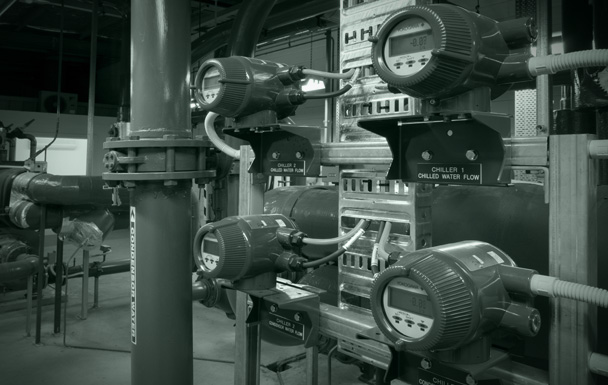

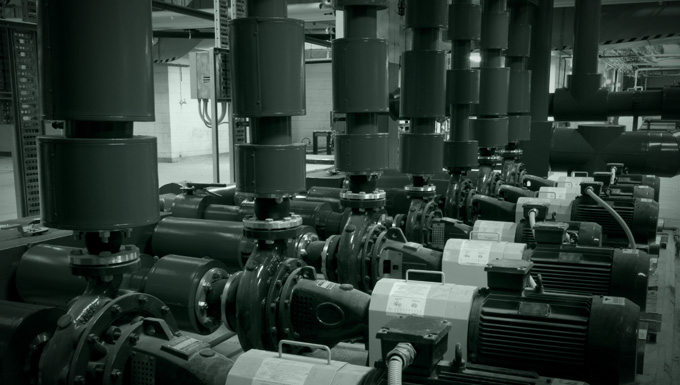

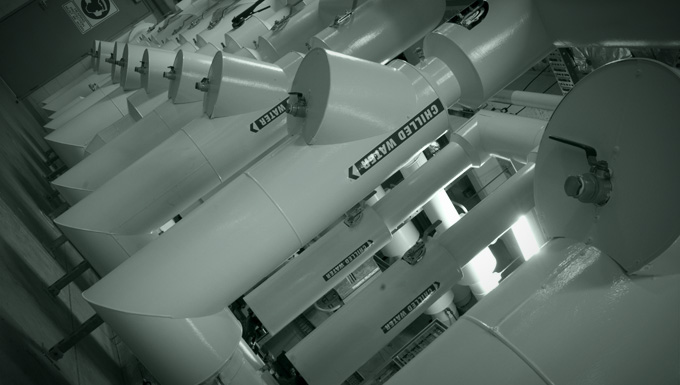

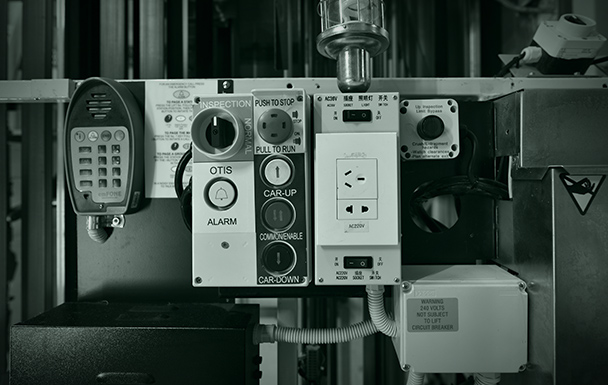

- Thermal plant connected air-conditioning

- High-efficiency condensing boilers

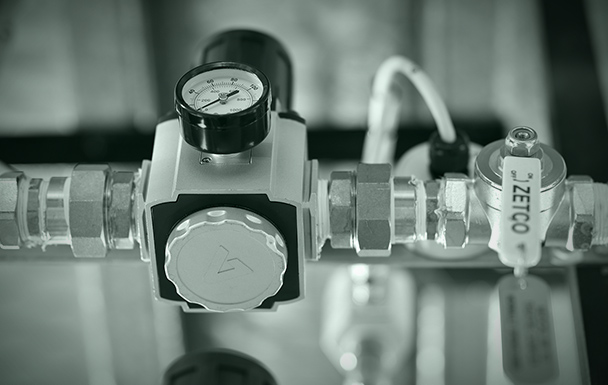

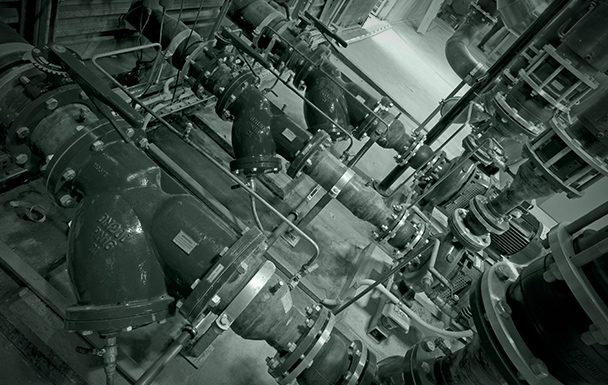

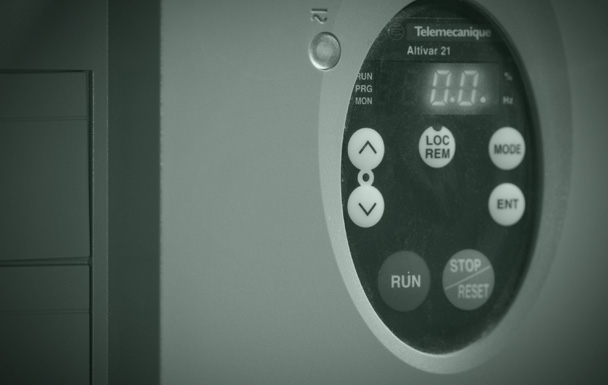

- Variable speed pumping

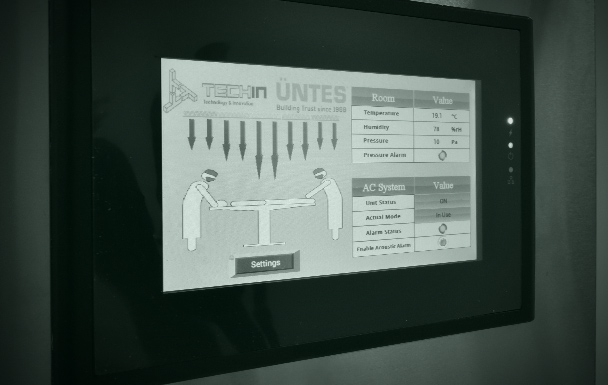

- Pressure controlled variable outside air

- Occupancy sensing setpoint control and setback

- Monitored fume-cupboard sash positioning

- LED lighting with local dimming control

- Occupancy sensing lighting control and setback

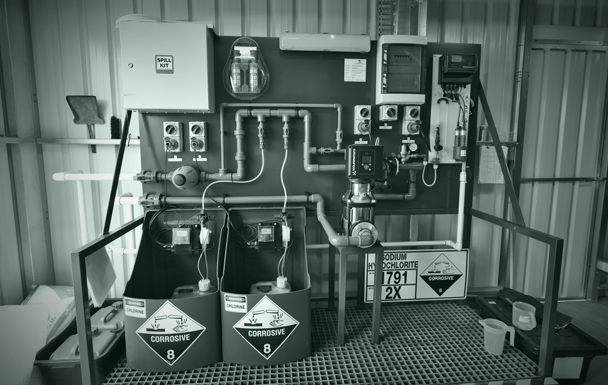

- Scrubber tanks with neutralising chemicals

Improvements:

The space has been fitted with high-grade finishes and service provisions, including:

- Laboratory-grade benches

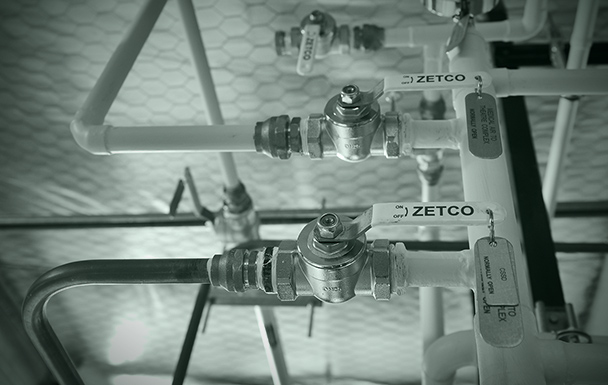

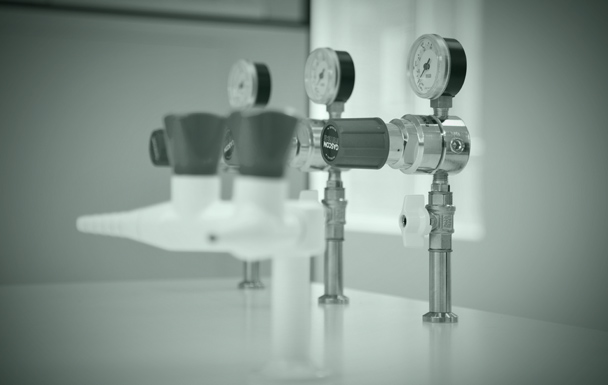

- Ultra-high purity gases – oxygen, hydrogen, acetylene, nitrogen, argon, nitrous oxide, carbon dioxide

- Compressed air

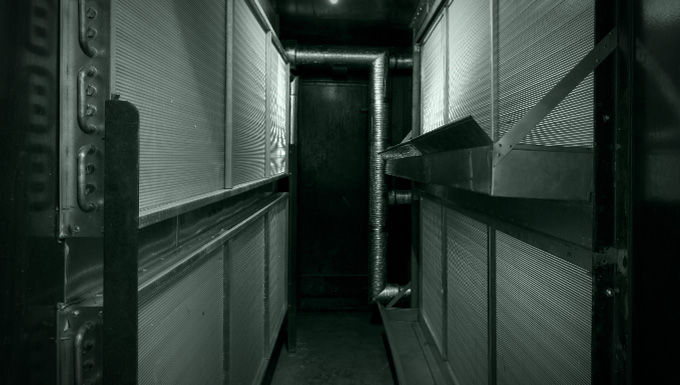

- Laboratory-grade laminar diffusion

- LED lighting with occupancy sensing and CBUS control

- Eight new fume cupboards.

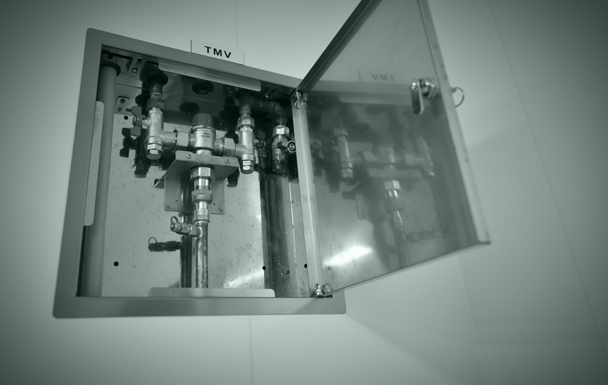

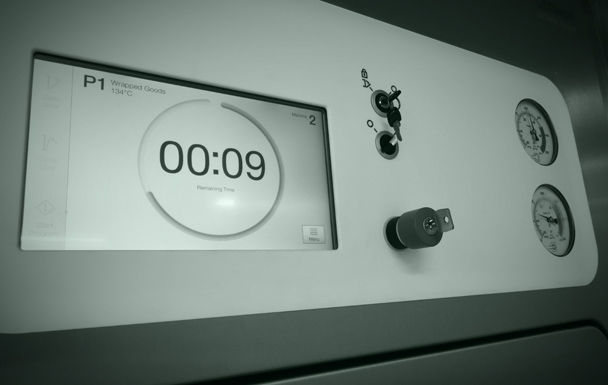

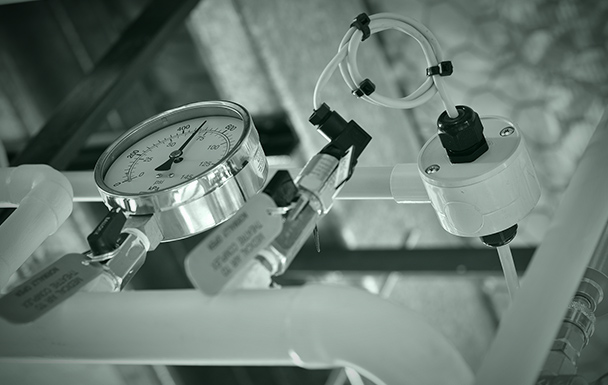

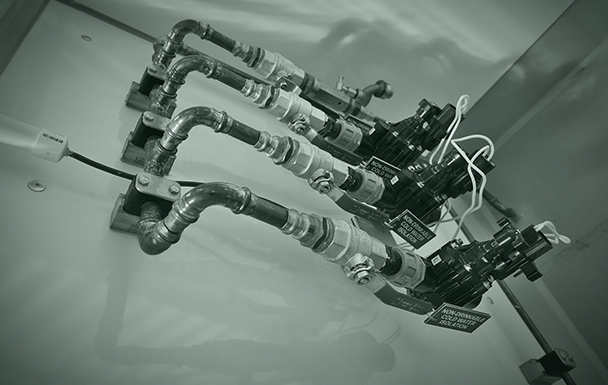

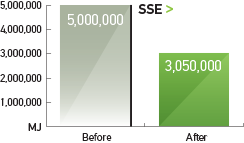

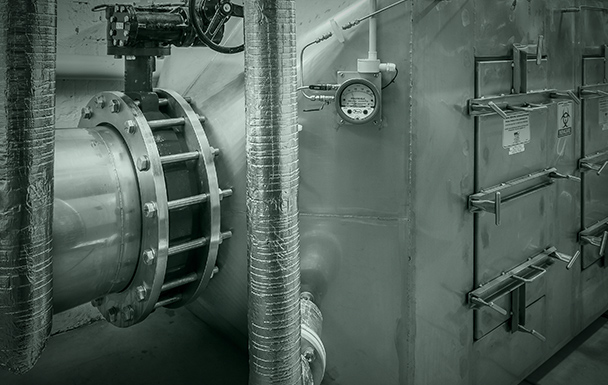

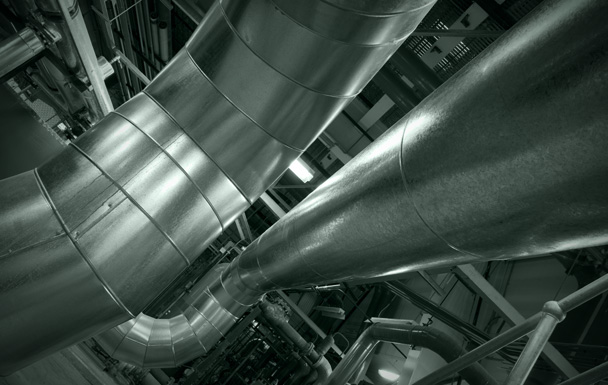

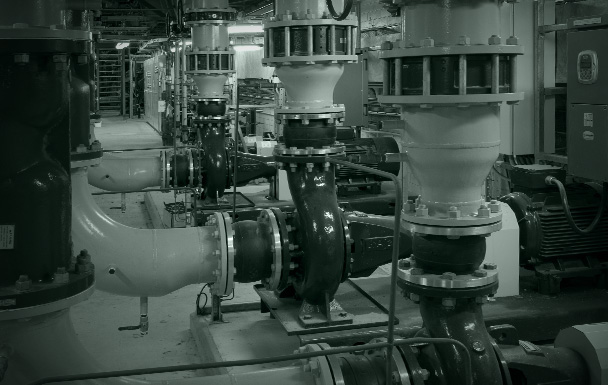

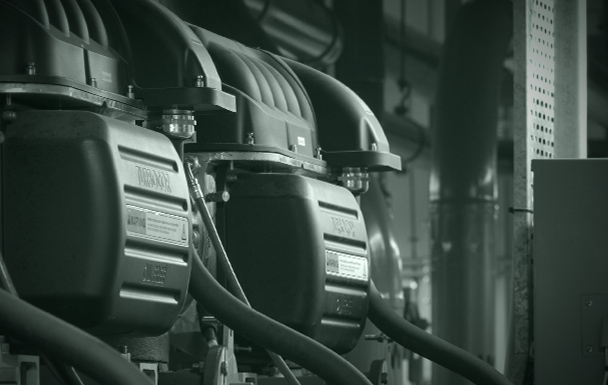

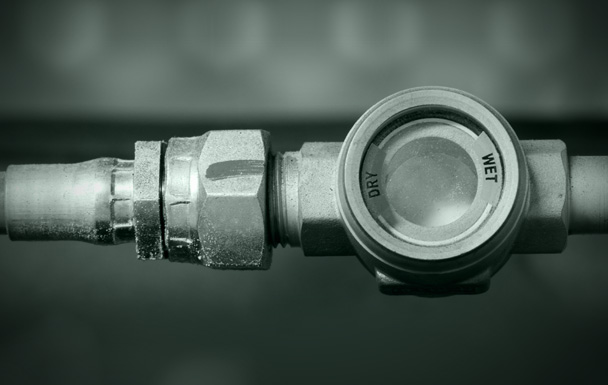

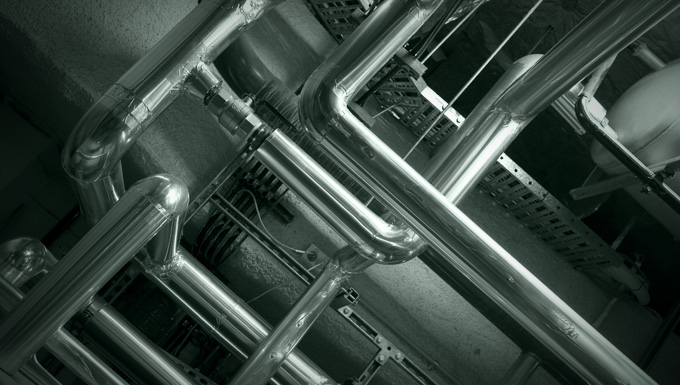

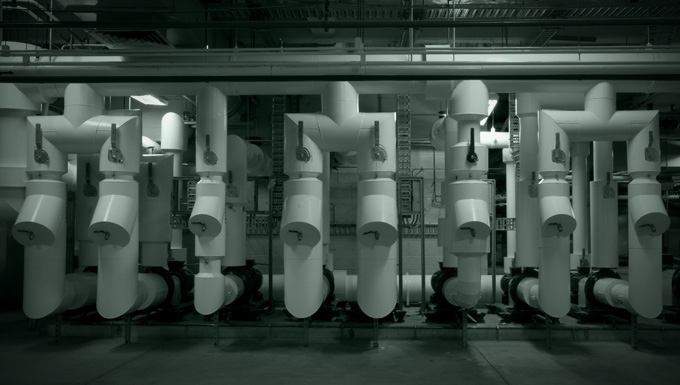

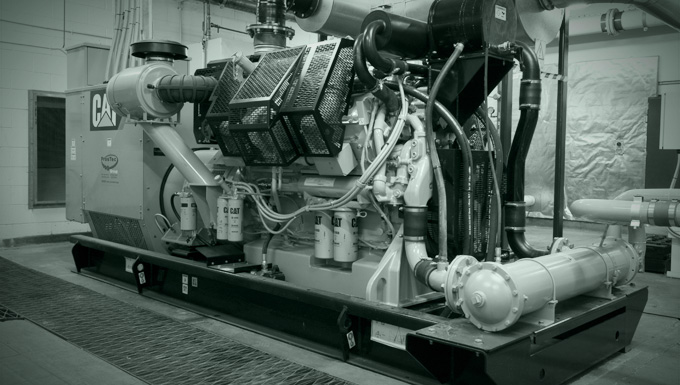

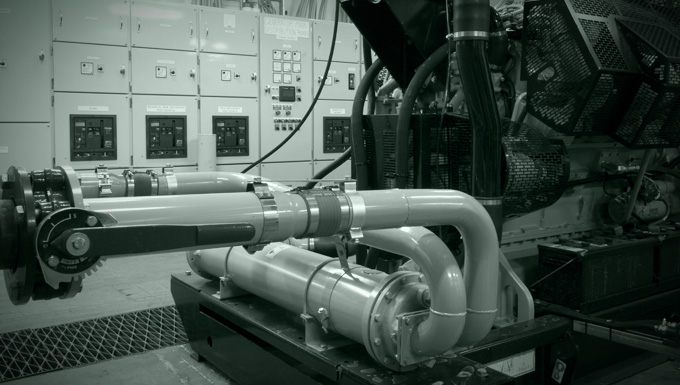

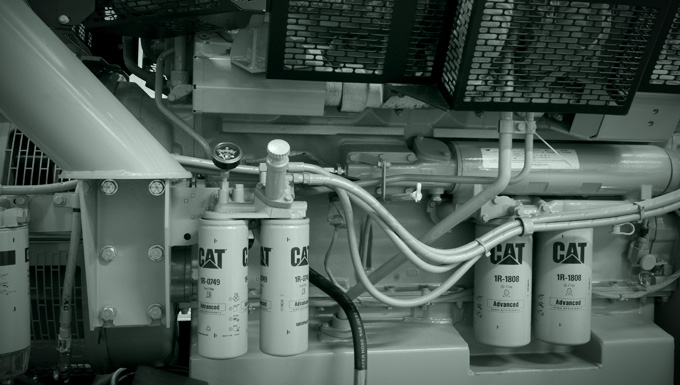

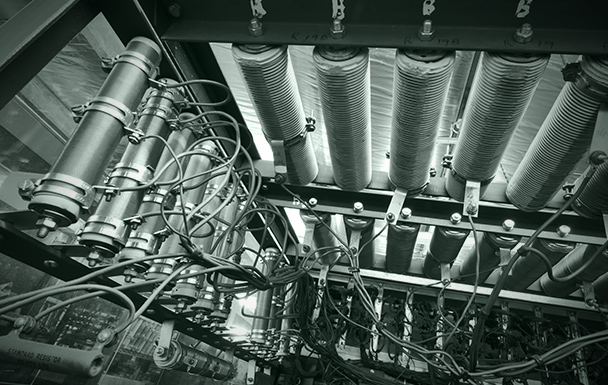

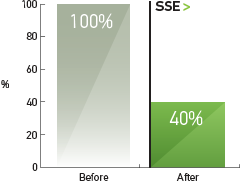

The mechanical services for the space are connected to the thermal plant located within the adjacent building, however the existing plant was upgraded to provide greater efficiency and capacity to service the newly created thermal network. Pipework takeoffs were also provided to enable future connection of a third adjacent building.

Services:

- AV integration

- Electrical (power & communications)

- Fire Protection

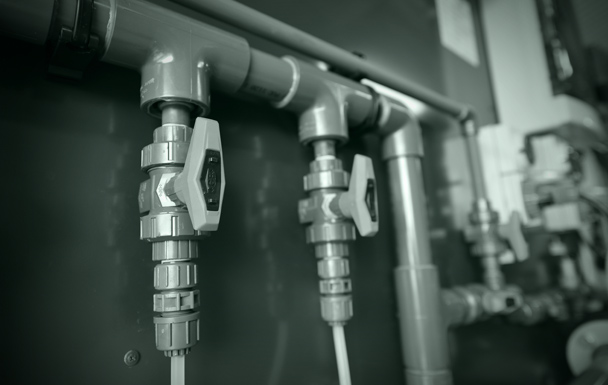

- Hydraulics

- Laboratory gases

- Mechanical

Associated Project Partners:

- Sarah Constructions

- Walter Brooke & Associates

- Watson Fitzgerald & Associates

- Air Con Serve

YEARS

YEARS